Honda Cars India reports domestic sales decline in November 2021; exports are up at 1,447 units

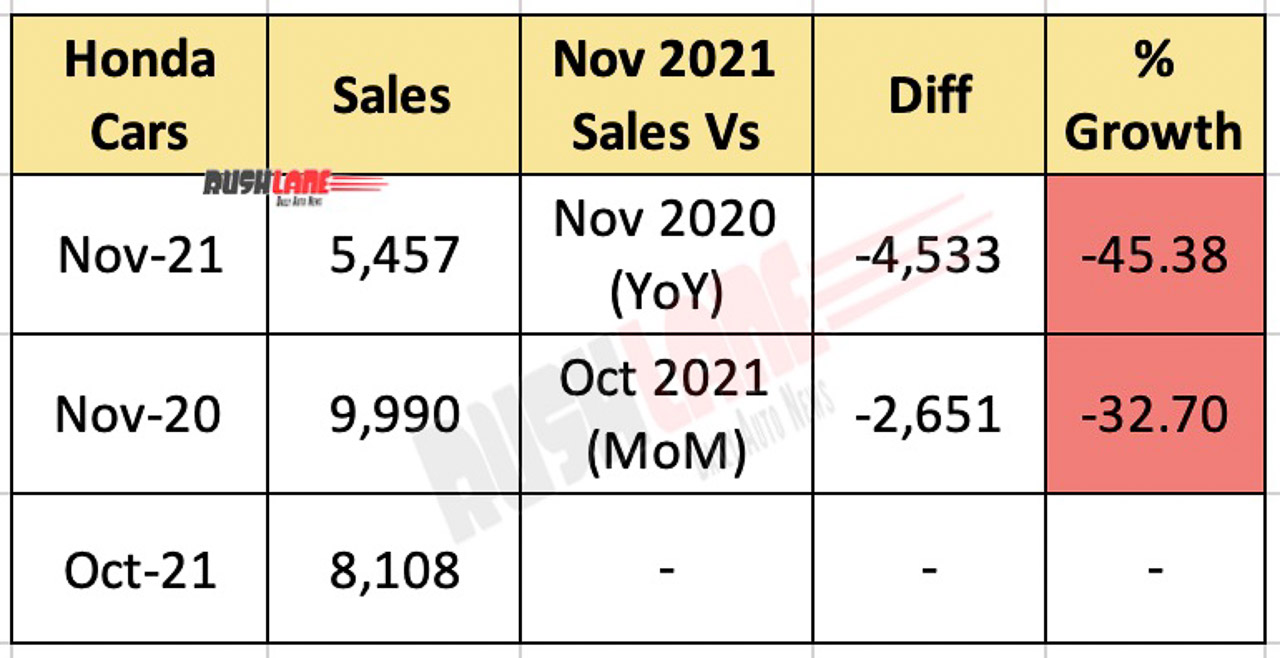

While production output continues to be prioritised, supply chain shortages are resulting in lower than optimum production output. Honda Cars India reports domestic sales of 5,457 units in November 2021. YoY decline stood at 45.38 percent at volume loss of 4.5k units.

A year earlier sales was reported at 9,990 units, and exports at 31 units. Exports in November 2021 improved to 1,447 units. With the addition of exports, total sales in November is reported at just over 6.9k units. Honda sells the 4th gen City, 5th gen City, Amaze, WR-V and Jazz in India.

Production constraints have wiped out production from 10k units to almost half. HCIL coped with chip shortage by resorting to non-production days in November. MoM sales decline is reported at 32.70 percent. Volume loss is reported at 2,651 units, down from 8,108 units in October 2021.

Non-production dates in November 2021

Rajesh Goel, Sr. Vice President and Director-Marketing & Sales, Honda Cars India Ltd said, “Despite consistent demand in the market, supply-side issues owing to the global chip shortage remain a concern. The company had to resort to non-production days in November’21 because of the same.

We have been selling our entire production stock during the last few months and making all efforts to meet the market demand as much as possible.” With Rajesh Goel resigning from HCIL in December 2021, Yuichi Murata has been appointed Director, Marketing and Sales, Honda Cars India Ltd.

Lower auto dispatches

There’s little clarity on when supply chain disruptions will be more manageable. Until then, one can expect production output to be lower than normal. This can extend for the next few months. Production constraints mean manufacturers are unable to meet current demand. This is being handled through longer delivery date estimates to bridge the supply-demand gap.

At the same time, manufacturers are revising new vehicle launch dates. With production schedules chock-a-block, its best to not further squeeze the system. Currently, all focus is concentrated on timely procurement in order to speed up production schedules.

While there has been some growth spurt in some months, for the most part constraints have been in continuity for about 20 months now. While production in 2020 was largely affected by Covid-19 lockdown restrictions, in recent months, the global chip shortage has hampered production, and thereby dispatches. Industry trends sees a fair number of manufacturers dealing with lower dispatches.