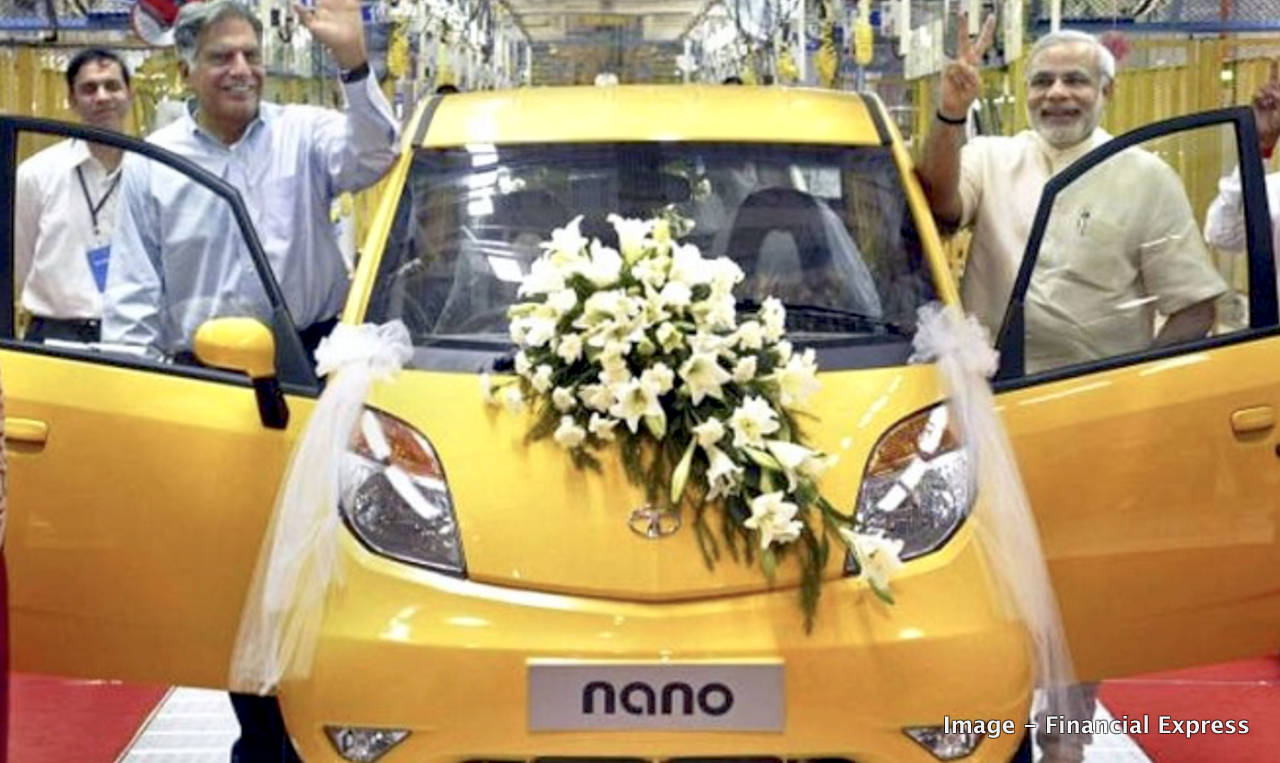

It was back on 2nd June 2010, that the Tata Motors Sanand plant was officially inaugurated by then CM of Gujarat, Mr Narendra Modi and Chairman of Tata, Mr Ratan Tata. The reason this plant was built, was to produce the Rs 1 lakh car, the Tata Nano. Unfortunately, that car never took-off, in spite of several attempts. And thus, in all these years, the Sanand plant never touched full capacity.

But that changes today. Not because of Nano, but because of Tata’s new generation cars – Tiago and Tigor. Tata Motors announced today that their Sanand plant has achieved 100% capacity utilization.

To meet growing demand, Tata Motors today announced ramping up production at its Sanand plant, which is operating at 100 percent capacity utilization, having rolled out 4,50,000+ units to date. Tata Motors Sanand plant is among the company’s fastest growing factories and contributes to 60 percent of the company’s cumulative PV production. The 5,00,000 unit production mark will be celebrated in October 2018.

Tata Motors has put its foot through the door on the back of new product launches in recent years leading to growth guided by its turnaround strategy to optimize all business functions effectively. Full capacity production at Sanand helps the company deliver vehicles faster to its growing customer base. Sanand plant is transforming itself as a Center of Manufacturing Excellence and is key in establishing the Tiago and Tigor brand.

Spread over 1,100 acres of land, Tata Motors Sanand plant began opertions as a single model plant in 2010, when Nano production was shifted from Singur. Currently, the tech advanced unit is charged with multi-model production. The flexible assembly line manufactures Nano, Tiago and Tigor models. This includes 21 variants with 150 vehicle combinations. Engine production includes Revotron 1.2L – Petrol (Manual & Auto Transmission), Revotorq 1.05L – Diesel, 624 CC, MPFI – Petrol (Manual & Auto Transmission) and 1.2 NGTC – Petrol (Manual & Auto Transmission).

Tata Motors is mapping out modular architecture plans between Pune and Sanand plants to to meet product expansion plans. Mayank Pareek, President, Passenger Vehicle Business Unit, Tata Motors said, “We, at Tata Motors, have been working aggressively towards our core strategy of Turnaround 2.0, aiming to ‘Win sustainably in PVs’. A lean manufacturing process plays a key role in our growth strategy enabling the Sanand plant to contribute around 60% of the overall PV production. The plant has evolved to become a modern, state-of-the-art facility and is playing a vital role meeting aspirations of Tiago and Tigor customers. The plant has already achieved WCQ 3 level in quality standards and we are extremely proud of this achievement.”

Tata Motors Sanand plant is the company’s newest production unit to optimise functionality through leveraging tech with 190+ robots, and high levels of automation for increased productivity. With focus on driving in electric vehicles in India, Sanand plant is charged with production of Tigor EV, which for now is being supplied as part of a commercial deal as per the EESL order.

Awarded the CII GreenCo Platinum Certification in June 2018, this zero discharge plant has a systematic hazardous waste disposal process, and uses 30-35 percent of renewable energy from total power consumption. 2MW of roof top solar panels and off-site wind power mills with capacity of 9MW are in use. A 180 acre green belt is maintained with waste water. Sanand plant reports 1,300-tCO2e (Tonnes of carbon dioxide equivalent) reduction in Carbon Emission on an average per month in FY18.